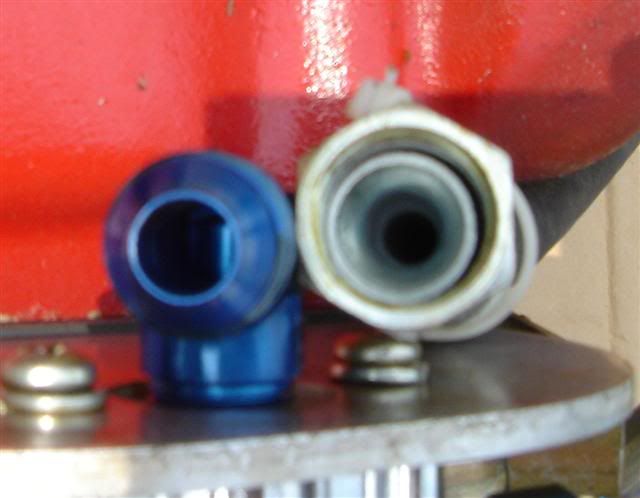

The pic on the left is -6 JIC (AN) as is the one on the right. The one on the left is your typical Aeroquip/Earl's 300 psi fitting. The one on the right is 4000psi hydraulic.

They screw together.

They don't leak.

And your fuel pressure regulator is going to read 7psi when you set it up. But the internal diameter on the left is 3/8" and the one on the right is 1/4"

The area of 3/8" is .110" and the area in 1/4' is .049. Less than half.

So at 5500 rpm, your big inch motor is going to be starved for fuel. And melt down.

Thread: Destroy Your Engine For $20

Results 1 to 18 of 18

-

Contributor

- Join Date

- Oct 2008

- Posts

- 4,796

07-21-2009 11:29 AM

-

07-21-2009 11:35 AM

and you know this how???

-

07-21-2009 11:40 AM

Similar problems with the sea strainers. Intake hose (from the outdrive) is about 1 1/4" inside diam. Most fittings (to the strainers)the inside is about 3/4". You loose volume. Overheating possibilities. I have HD insustrial fittings so all the inside diam. are larger than a standard "1 inch" NPT fitting.

THanks Chris. Good point.Life is: what happens... when you plan something else.

-

07-21-2009 12:31 PM

You don't really lose anything because the water entering the gimbal is coming through a .75 ID threaded plastic retaining ring, then through a .875 ID inlet hose, back through a .75 ID retaining ring, to the .875 ID water inlet fitting (plastic hose barb on the inside of the boat), to the 1 1/4" ID hose to the strainer or pump.

Chris...you ran -6 on a big motor? Fittings are cheap...-8 minimum even on small motors.

Fittings are cheap...-8 minimum even on small motors.

Either way, sorry to who it happened to!

-

Banned

- Join Date

- Nov 2008

- Location

- Where the summer never ends

- Posts

- 4,346

07-21-2009 12:35 PMRight,,but u can't loose volume with a seastrainer anyways,,unless its to small of a seastrainer.

It fills up and the pump gets it from tehre sp it really has nothing to do with the inlet hose going to the strainer unless your engine sucks it dry.

I DO AGREE ON THE OIL LINES TOUGH !!

-

Contributor

- Join Date

- Oct 2008

- Posts

- 4,796

07-21-2009 12:43 PMNot a big motor on this one. And fortunately I saw this on my buddy's boat before it became a problem- bigger motors going in.

I posted this to illustrate a very common mistake made by alot of somewhat knowledgeable people. I own a business that deals in high-pressure fluid power so I see this stuff and get to see the differences. many people assume if it screws together, it's compatible. Fluid power distributors are the worst on this. The have no exposure to low-pressure stuff typically. It's not tough to get good volume at 4,000 psi. At a little less than 2% of that pressure- 7psi, flow is critical.

And then there's oiling systems- exact same problem.

-

Founding Member / Contributor

- Join Date

- Oct 2008

- Location

- Socialist Republic of Washington State

- Posts

- 1,027

07-21-2009 01:32 PMEven better is to use a straight male and then use a hose end with a sweeping 90 degree arc instead of the 90 right angle in the Blue fitting shown.

32' Fever (Off to Syracuse) and 36"Gladiator; FORD powered

32' Fever (Off to Syracuse) and 36"Gladiator; FORD powered

Cause somebody has to!

-

Registered

- Join Date

- Nov 2008

- Posts

- 285

07-21-2009 09:45 PMYou can't considder the sea strainer as a reservoir unless you have somewhere for air to get in. You can't draw water from a sealed container unless air can get in.( unless you are drawing it into a vacuame) The size of the inlet will be a restriction. All of the small restrictions add up to restrict water flow.

-

Contributor

- Join Date

- Oct 2008

- Posts

- 4,796

-

Founding Member / Super Moderator

- Join Date

- Oct 2008

- Location

- West Michigan

- Posts

- 37,358

- Blog Entries

- 44

-

Registered

- Join Date

- Nov 2008

- Posts

- 285

07-21-2009 10:15 PMChris - I agree but untill the air gets to the strainer the restriction of the inlet hose and it's fitting is the limiting factor.

-

07-21-2009 10:46 PM

A #6 fuel line becomes inadequate as a primary feed around 550 hp. My guess is that first fitting shown would have only been good to about 400 hp maybe.

On the strainers remember 70 mph equals 71lbs of pressure. At 100mph it is seeing 144lbs. Strainers are always under pressure while boat is at speed. I have tested dump valves and steam valves in strainers and witnessed a 250lb pressure gauge explode on a 140mph run.

-

-

-

Founding Member / Super Moderator

- Join Date

- Oct 2008

- Location

- West Michigan

- Posts

- 37,358

- Blog Entries

- 44

-

-

Contributor

- Join Date

- Oct 2008

- Posts

- 4,796

07-29-2009 07:09 PMThe intake manifold usually goes first

-

07-29-2009 07:41 PM

The highest pressure is in the stainer the motor would see 15lbs. We worked through seven variations in the superv's 10 years ago. Tried the check valves with different springs, tried adjustable steam valves. In the end there was one pick up and one swirl can feeding both motors and and the can had a #8 hose dumping off the top. Motors ran with 15 lbs.

Destroy Your Engine For $20

Destroy Your Engine For $20