Thread: Todays Boat Construction

Results 41 to 60 of 166

-

-

Registered

- Join Date

- Nov 2008

- Posts

- 310

01-29-2009 08:12 PM

i don't think platinum every used a autoclave. to find and use an autoclave big enough to fit a 40' plus hull mold in it would be extremely expense. i thought that KR racing when first in business with Platinum might have done one or two boats in ohio but not sure about the autoclave process being done.

other than that, matbe the Victory guys in the middleast are doing them in an autoclave.

skater is still using mainly balsa-core, epoxy and just vacuum bagging

mti- not sure but looks like just vacuum bagging and epoxy

doug wright and outerlimits are the only 2 i know of the are using impregnators and post curing. and possible mystic. these two steps, using the impregnator and post curing are the best way to maximize the full potential strenght of the epoxy resin by post curing in a make shift oven and the impregnator to gain the strongest glass to resin weight ratio.

as far the delam on callan, who knows but other have had the same problem. one of the fountain v's -possibly pier 57, jay muller's 40 motion.

biggest problem is improper vacuum bagging and not having 100% bonding of core to glass

-

01-29-2009 08:26 PM

-

Registered

- Join Date

- Nov 2008

- Posts

- 310

-

registered

- Join Date

- Oct 2008

- Posts

- 2,001

-

01-29-2009 11:26 PM

-

01-30-2009 01:40 AM

Balsa is not the issue; in fact, it is an excellent structural core material. End grain balsa will not transport water across the hull. It can happen to foam, just not as prevalent. Ever had a wet Whaler? Most of the issues stem from lamination of the core to skin...and its usually the top surface of the core that gives way.

Improper fabric impregnation techniques are the issue. Poor resin to structural fiber ratios and poor wet out or "dry spots" cause problems. It's why almost every competent builder wets the fiber out completely before it goes into the mold rather than "sucking" the resin in under a vacuum like the SCRIMP and similar processes. The vacuum bagging process these builders employ only removes the excess resin. Excess resin adds unnecessary weight and does not increase the structural capability of the composite.

-

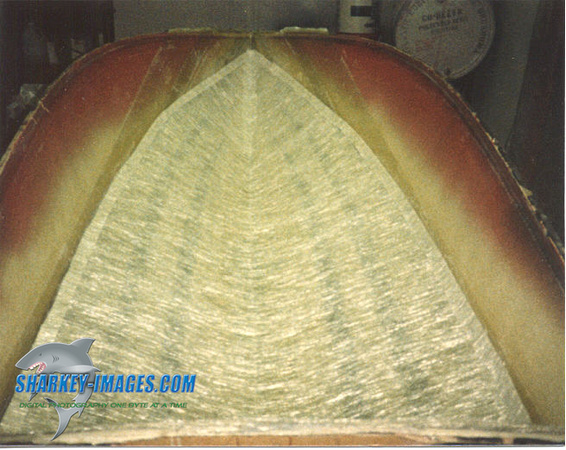

SHARKEY-IMAGESGuest01-30-2009 08:54 AM

How about a look at this ?

http://sharkeyimages.zenfolio.com/p541027519/slideshow

.

-

01-30-2009 09:58 AM

Balsa is a great material from the single stand point of Cost it does However have several Achilles heels, Some of which is the transfer of impact directly to the internal skin and it's lack of resilience leads to a laminate that has to be designed a little heavier and is more failure prone in highly stressed conditions.

The comparison of the structural plastic cores which cost twice what balsa does to the cheap two part foam in a whaler is not really fair and not accurate.

The Coring such AS Core Cell are really The Super Cores and the ultimate in construction material. They have all the desired physical properties for high performance composite work, made from engineering plastics (SAN used in plastic cigarette lighter bodies) in highly controlled manufacturing processes.Slippery when wet. PODLESS TUNNEL www.cheetahcat.com ,Repairs, Modifications and Truing Cheap reliable speed.

-

registered

- Join Date

- Oct 2008

- Location

- Edgerock, MD

- Posts

- 1,947

-

Contributor

- Join Date

- Oct 2008

- Posts

- 4,796

01-30-2009 10:53 AMJim Dyke (KR) told me that none of the boats were done in an autoclave. But, I was in Italy and visited Tencara and saw them remove an offshore cat ( I believe it was a 43) from their autoclave. I still have a photo but no idea on which of a couple hundred disks it's on. It gets kind of blurry- Tencara/Victory/KR/Platinum...

I wouldn't swear to it, but I remembered Callan's boat being a Tencara/Italy-produced boat.

-

01-30-2009 11:00 AM

Sharkey looks like the Balsa was bonded with a putty which is good and bad. A little too much vacuum and you pull the resin from the putty and the hotcoat into the core leaving Only the putties fillers behind which do nothing.

Slippery when wet. PODLESS TUNNEL www.cheetahcat.com ,Repairs, Modifications and Truing Cheap reliable speed.

-

Registered

- Join Date

- Nov 2008

- Posts

- 310

01-30-2009 11:04 AM

brad i would argue that your completely wrong. take a piece of balsa core and a piece of Core cell and stick them in a bucket of water. i will admit that Balsa core is a good structural core as some of the high end foams - core cell, airex. but balsa is heavier and sucks up a lot of resin in the wet out process. i have worked with both balsa and the foams and i only use foam now. my first experience with balsa, i thought i had saturated the balsa properly after wetting the core out and letting it sit for several minutes and then applied my top layer. i came back the next day and had to redo that section since the balsa coring actually sucked all the resin out of the glass laminate, making it to dry and improperly bonding with the balsa. i have found using solid sheet foam and cut, fitting what i need works the best for me since i'm left with least amount joints.

steve 1 is right the "floatation" type foam used in whalers and other recreation boats is not a true structural foam and not to be used in a laminate structure at least for a race boat and also you right on the 'dry spots' if using a impregnator machine. i think that sometimes that in trying to acheive a lighter, stronger boat that the use of the impregnator is used to much.

as for vacuum bagging a wet laminate vs infusion. i'm not a big fan of infusion since if it is done up agianst a gelcoated surface and if a core is invloved, no one will ever know if there is a bonding issue on the outer skin since it can't be seen because of the gel coat pigment color. and also the vacuum bagging process does not 'suck' all the extra resin out. it does pull some of the excess, but it is not used or designed to do what the impregnator machine does which is too impregnate the glass fiber with an exact amount of resin. basically you can not go in there and hand layup a piece and expect the vacuum bag system to pull the all the excess resin out of the laminate and get down to the glass to resin ratios that you would get using a impregnator.

-

Registered

- Join Date

- Nov 2008

- Posts

- 310

-

-

-

SHARKEY-IMAGESGuest01-31-2009 12:42 AM

I was never fond of the putty.

My Bullet 130 I used hand laid chop mat very wet, pre-wet the balsa and pressed into the glass. She is 18 years old, been through hell and back... Still strong as ever...

See the whole lay up here:

http://sharkeyimages.zenfolio.com/p570079324/slideshow

-

01-31-2009 02:08 AM

Tim very nice neat work!

Slippery when wet. PODLESS TUNNEL www.cheetahcat.com ,Repairs, Modifications and Truing Cheap reliable speed.

-

SHARKEY-IMAGESGuest01-31-2009 10:17 AM

Thanks Steve!

The one thing I changed in the future layups was I feathered the chop mat as it ran up the bow so it would not to leave such a solid edge.

A shot of the final inside layer:

-