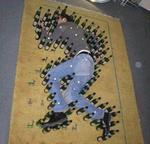

here they are. the one on the left is my old one that I bought the one on the right is the one we made. from a 9 inch drop to a 12 inch drop

Thread: Trailer hitch

Results 21 to 39 of 39

-

11-14-2009 12:20 PM

-

11-14-2009 12:45 PM

Have you thought about redoing the toung on the enclosed trailer? Kind of meet it in the middle. I am not a big fan of huge drops. It puts a lot of pressure on the hitch. Another thing that could help would be a Torklift Superhitch.

http://www.hitchsource.com/trailer-h...-c-24_157.htmlTaking Over the World One Thread at a Time

The Penguin Cometh

-

11-14-2009 01:19 PM

I figured with shortening how far it sticks out and the new gusset that it would be ok

-

-

Charter Member

- Join Date

- Oct 2008

- Location

- Appleton, Wisconsin. Where we have 2 seasons... winter and road construction

- Posts

- 4,120

11-14-2009 02:25 PMTake your old hitch and mount it in the receiver tube. Now measure from the center of the ball to the receiver tube. Now do the same thing with your custom hitch. If the distance is any longer with your custom hitch, you are asking for big troubles. Especially if your receiver tube is already bent.

•_•_•_▬_▬_▬_•_•_•

-

11-15-2009 10:56 AM

The arm was so long with my original hitch and I hauled some heavy machinery with it and it did bend it slightly. We put the truck on a frame machine and got it back to good.

I will do that measurement but I am willing to bet it is going to be alot shorter distance with the custom hitch

-

11-22-2009 01:56 PM

OK did the measuring. Old hitch is 14" new one to same point is 11"

-

Banned

- Join Date

- Nov 2008

- Location

- Where the summer never ends

- Posts

- 4,346

11-22-2009 02:02 PMI think thats ok , but i would NOT trusst that ball mount !!!!

-

11-22-2009 02:21 PM

That's the same mount that came with the one i bought. it's 1/2 " thick

-

11-22-2009 05:24 PM

Agreed. Had a crew cab Ford with 8 inches of lift and 38"s. Have the same set up your uncle built (nice job). After a year of towing, was doing some maintance and found the two front mounting tabs broke free from the reciever frame and the middle set cracked (only 6 mounting points total). I up graded to a 16,000 lb 2" reciever. There is also a 3" reciever that is rated at 20,000 lbs. The standard class 5 10,000 lb reciever is not going to cut it for long, promise... I got lucky and didn't loose a load or worse off kill anyone.

-

Charter Member

- Join Date

- Oct 2008

- Posts

- 122

11-22-2009 07:56 PMWhy not make a couple of bars to go diagonally from the bottom of the mount and up & outwards to the trucks frame? A 3 point hitch. That'll address the push/pull forces from the trailer and also prevent the sideways forces, which I haven't seen addressed here yet. Can't beat a triangle design.

-

Banned

- Join Date

- Nov 2008

- Location

- Where the summer never ends

- Posts

- 4,346

-

-

-

11-23-2009 12:11 PM

I don't want my hitch on all the time so that wouldn't work for me. I will have to crawl under there and inspect the receiver. Might have to come up with some ideas for adding a little strength to that. I rarely tow anything very heavy at all but would rather be safe than sorry

-

Charter Member

- Join Date

- Oct 2008

- Posts

- 122

11-23-2009 01:06 PMDon't have to be mounted permamently, but with pins just like your reciever. I see this quit often on extreme lowered hitches.

-

11-23-2009 01:41 PM

I will have to look into doing something like that. The more strength the better!

-

Registered

- Join Date

- Dec 2009

- Posts

- 117

12-31-2009 11:36 PMlooks good! is your uncle a cert. welder?

-

Reciever

Reciever